NATIVE 4.0

The Salvagnini DNA is based on FLEXIBLE AUTOMATIONa native concept, evolved thanks to new technologies, still actual and alid for Industry 4.0 paradigm.

In 1985 Salvagnini installed in NC, USA an AJS (Automatic Job Shop), the first lights-off factory, a combination of automatic machines, communicating in line and integrated to the customer’s MRP.

Customer's request:

- Overnight elaboration of incoming orders collected in MA and transmitted daily within 22:00 in NC.

- Automatic optimization of manufacturing flow.

- Average daily production of 600 kits (4500 different parts) every day in a different mix.

Salvagnini's solution

- 12 Salvagnini systems connected in line (FMS), integrated downstream with painting lines and assembly dept.

- Proprietary software to manage each FMS.

- Integration with the company’s MRP.

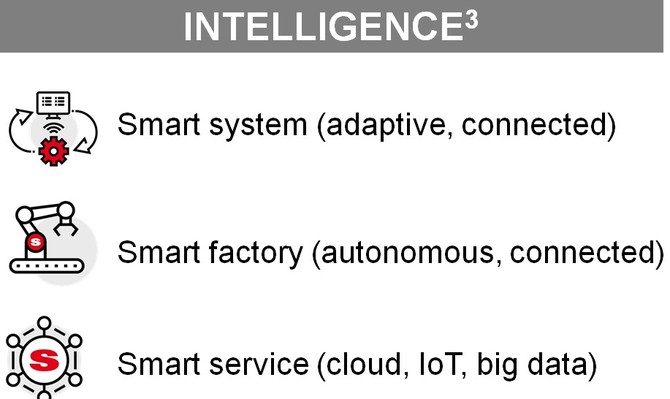

New 4.0 technologies changed the concept of flexible automation, as machines become deeply interconnected and adaptable, able of exchanging high level information between themselves and with the external environment.

Logistics: from connected machines, lines ► smart logistics, integrated with company ERP’s and to upstream/downstream operations/logistics.

New technologies (digitalization) widened horizons, bringing intelligence outside the factory, in terms of connection and communication via IoT , creation of a virtual copy of the physical world; support in data management; CPS autonomous decisions.