AJS™

Automatic job shops: not for mass production

Salvagnini's expertise in integrating sheet metal processing machines is well-recognized. The first totally automatic flexible factory (AJS) for lights-out production of electrical cabinets was supplied to America back in 1984. It is just one of the numerous examples that demonstrate Salvagnini's ability to offer and produce flexible systems that are both automatic and integrated. These solutions are specifically designed to support the latest production techniques such as kit production, lean production, unmanned production, JIT production and batch one.

100% flexible automation and lean production

A Salvagnini AJS (automated job shop) system plans and executes sheet metal panel production using punching, shearing, laser cutting and bending operations in a manner that is not only totally automatic and flexible but also perfectly integrated and lean.

Each Salvagnini AJS represents a concrete response to the demands of lean manufacturing, the philosophy which advocates implementing techniques and actions in the factory in order to optimize time, resources, activities and productivity as well as to improve product quality. Indeed, each and every detail is designed to provide the very best in sheet handling, punching and shearing, cutting, bending, programming and diagnostics.

The different types of AJS systems implemented depend on customer requirements in terms of application sector, production mode and company philosophy.

Intelligent systems

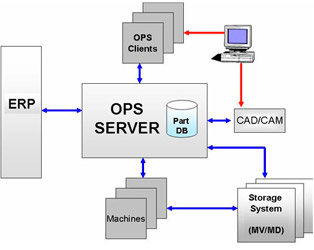

Salvagnini offers the proprietary Opera-OPS software for efficient and effective production management even on a complex combination of systems.

Developed by Salvagnini, Opera-OPS is a software application for communicating with the customer's MRP/ERP management systems so that the production process can be completed in a manner that is totally flexible and automatic.

To manage the automatic warehouses required by an automatic factory, Salvagnini offers the Opera-WMS software which allows the raw material and partly machined workpieces to be controlled throughout the entire production process.