FlexCell - Flexible bending cell

Minimum cost per bend and maximum profit.

- The tendency towards smaller batch sizes generates inefficiencies, either as a result of continuous retooling or because of a high number of press-brakes aimed at reducing set-up frequency.

- Profit from the bending process gets smaller and smaller and causes aggressive price policies in the marketplace.

- Manual bending is more prone to errors and makes it harder to ensure consistent repeatability in terms of quality and time.

- The bending technologies available offer different, non-compatible ranges of feasibility.

- Machine data often has to be managed and transferred manually.

- Automatic tool set-up in masked time means production can run smoothly and without interruption, even in the case of batch-one production.

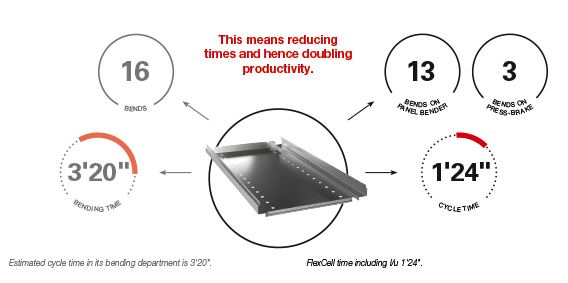

- Offering high-speed manufacturing and flexibility, FlexCell ensures a highly competitive cost per bend.

- Operations on the panel bender are performed automatically and the process software ensures precise control of production times.

- Having two complementary technologies means that all restrictions on bending feasibility are removed.

- OPS FlexCell software manages, schedules and records all the production data without error in masked time.