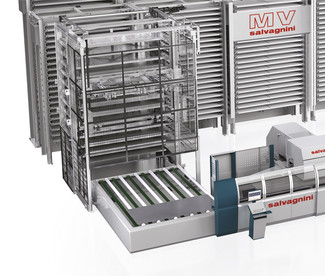

MV - Automatic tray store

MV COMPONENTS

MS station:

Tower for simply tray shelving.

MA station _________________________

Tower for tray store feeding equipped with a motorized “pegged bed” carriage and a reference system to allow the correct positioning of the pack of sheet metal to be processed or the picking up of a pack.

MIS.SPV station and MIS.SDV:

Tower for tray exchange equipped with a carriage (SPV) or with a double carriage (SDV) to feed or unload a Salvagnini feeding or unloading connection. This is the basic interface station (picker crane missions are not masked).

_____________________ MIS.SSV station

Tower for tray exchange equipped with a scissor table to feed or unload the connection of a Salvagnini system. This is an advanced interface station (picker crane missions are half masked).

MIS.SSC station:

Tower for tray exchange equipped with a pair of chain conveyors and a scissor table to feed or unload the connection of a Salvagnini system. This is a highly advanced interface station (picker crane missions are fully in masked time).

_________________________ MIE station

Tower for trays auxiliary exit. It is equipped with a motorized carriage for tray exchange between:

- the store and the workshop, allowing the material deposited onto the trays to be picked up;

- the store and third parties machines.

SMD destacker _______________________

Tower with an integrated manipulator-elevator with suction cups, able to pick up the single sheets directly from different trays positioned inside the shelving and to transfer them to Salvagnini systems.

Suitable when small batches or lists of single parts different from one another are to be processed without any waiting time. SMD also allows to compact the same material present in more trays in the store and to create packs for MIE station (defrag function).