B3 - Press brake 4.0

- MM

- INCHES

Technical data

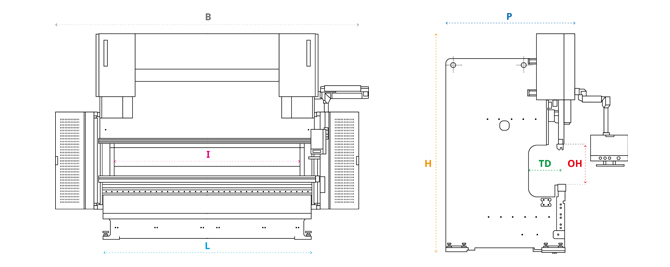

| Model | 60/2000 | 100/3000 | 135/3000 | 135/4250 |

| Maximum bending force [Tons] | 60 | 100 | 135 | 135 |

| Table length L [mm] | 2040 | 3060 | 3060 | 4250 |

| Distance between side frames I [mm] | 1740 | 2640 | 2640 | 3640 |

| Throat depth TD [mm] | 350 | 435 | 435 | 435 |

| Maximum speed [mm/s] | 250 | 250 | 250 | 250 |

| Bending speed* [mm/s] | 20 | 20 | 20 | 20 |

| Maximum stroke [mm] | 300 | 300 | 350 | 350 |

| Table-ram distance OH [mm] | 550 | 550 | 600 | 600 |

| Total lenght B [mm] | 3200 | 4270 | 4310 | 5310 |

| Total width P [mm] | 1875 | 1725 | 1735 | 1735 |

|

Total height H [mm] |

3025 | 3025 | 3295 | 3295 |

|

Maximum electrical consumption [kW] |

10 | 12 | 16 | 16 |

| Mass [kg] | 6200 | 8600 | 11700 | 13500 |

| Model | 170/3000 | 170/4250 | 170/4250XL | 220/3000 |

| Maximum bending force [Tons] | 170 | 170 | 170 | 220 |

| Table length L [mm] | 3060 | 4250 | 4250 | 3060 |

| Distance between side frames I [mm] | 2640 | 3640 | 3620 | 2650 |

| Throat depth TD [mm] | 435 | 435 | 520 | 520 |

| Maximum speed [mm/s] | 250 | 250 | 220 | 220 |

| Bending speed* [mm/s] | 20 | 20 | 18 | 18 |

| Maximum stroke [mm] | 350 | 350 | 450 | 450 |

| Table-ram distance OH [mm] | 600 | 600 | 700 | 700 |

| Total lenght B [mm] | 4310 | 5310 | 5330 | 4360 |

| Total width P [mm] | 1735 | 1735 | 2080 | 2080 |

|

Total height H [mm] |

3295 | 3295 | 3705 | 3705 |

|

Maximum electrical consumption [kW] |

20 | 20 | 20 | 26 |

| Mass [kg] | 11700 | 13500 | 19400 | 17000 |

| Model | 220/4250 | 220/5100 | 220/6100 | 320/3000 |

| Maximum bending force [Tons] | 220 | 220 | 220 | 320 |

| Table length L [mm] | 4250 | 5100 | 6100 | 3060 |

| Distance between side frames I [mm] | 3620 | 4620 | 5600 | 2630 |

| Throat depth TD [mm] | 520 | 520 | 520 | 520 |

| Maximum speed [mm/s] | 220 | 220 | 180 | 220 |

| Bending speed* [mm/s] | 18 | 18 | 18 | 18 |

| Maximum stroke [mm] | 450 | 450 | 450 | 450 |

| Table-ram distance OH [mm] | 700 | 700 | 700 | 700 |

| Total lenght B [mm] | 5330 | 6330 | 7400 | 4380 |

| Total width P [mm] | 2080 | 2080 | 2080 | 2085 |

|

Total height H [mm] |

3705 | 3705 | 3705 | 3755 |

|

Maximum electrical consumption [kW] |

26 | 26 | 26 | 39 |

| Mass [kg] | 19400 | 21500 | 23500 | 21800 |

| Model | 320/4250 | 320/5100 | 400/4250 |

| Maximum bending force [Tons] | 320 | 320 | 400 |

| Table length L [mm] | 4250 | 5100 | 4250 |

| Distance between side frames I [mm] | 3600 | 4600 | 3600 |

| Throat depth TD [mm] | 520 | 520 | 520 |

| Maximum speed [mm/s] | 220 | 220 | 220 |

| Bending speed* [mm/s] | 18 | 18 | 18 |

| Maximum stroke [mm] | 450 | 450 | 450 |

| Table-ram distance OH [mm] | 700 | 700 | 700 |

| Total lenght B [mm] | 5350 | 6350 | 5350 |

| Total width P [mm] | 2085 | 2085 | 2085 |

|

Total height H [mm] |

3755 | 3755 | 3755 |

|

Maximum electrical consumption [kW] |

39 | 39 | 45 |

| Mass [kg] | 25000 | 30000 | 27000 |

| Model | AU-TO 170/4250 | AU-TO 220/4250 |

| Maximum bending force [Tons] | 170 | 220 |

| Table length L [mm] | 4250 | 4250 |

| Distance between side frames I [mm] | 3640 | 3620 |

| Throat depth TD [mm] | 435 | 520 |

| Maximum speed [mm/s] | 250 | 220 |

| Bending speed* [mm/s] | 20 | 18 |

| Maximum stroke [mm] | 350 | 450 |

| Table-ram distance OH [mm] | 600 | 700 |

| Total lenght B [mm] | 5560 | 5560 |

| Total width P [mm] | 2170 | 2240 |

|

Total height H [mm] |

3290 | 3690 |

|

Maximum electrical consumption [kW] |

20 | 26 |

| Mass [kg] | 15500 | 21600 |

* Bending speed regulated by current standards.

** Automatic tools set up L = 3060 mm

Salvagnini reserves the right to modify this data without prior notice.

Technical data

| Model | 60/2000 | 100/3000 | 135/3000 | 135/4250 |

| Maximum bending force [US Tons] | 66 | 110 | 149 | 149 |

| Table length L [in] | 80 | 120,4 | 120,4 | 167 |

| Distance between side frames I [in] | 68 | 104 | 104 | 143 |

| Throat depth TD [in] | 13 | 17 | 17 | 17 |

| Maximum speed [ipm] | 590,6 | 590,6 | 590,6 | 590,6 |

| Bending speed* [ipm] | 47,2 | 47,2 | 47,2 | 47,2 |

| Maximum stroke [in] | 11,8 | 11,8 | 13,8 | 13,8 |

| Table-ram distance OH [in] | 21,7 | 21,7 | 23,6 | 23,6 |

| Total lenght B [in] | 126 | 168,1 | 169,7 | 209 |

| Total width P [in] | 73,8 | 67,9 | 68,3 | 68,3 |

|

Total height H [in] |

119 | 119 | 129,7 | 129,7 |

|

Maximum electrical consumption [kW] |

10 | 12 | 16 | 20 |

| Pound [lb] | 13668.6 | 18959.7 | 25794 | 29762.4 |

| Model | 170/3000 | 170/4250 | 170/4250XL | 220/3000 |

| Maximum bending force [US Tons] | 187 | 187 | 187 | 242 |

| Table length L [in] | 120,4 | 167 | 167 | 120,4 |

| Distance between side frames I [in] | 104 | 143 | 142 | 104 |

| Throat depth TD [in] | 17 | 17 | 20 | 20 |

| Maximum speed [ipm] | 590,6 | 590,6 | 519,7 | 519,7 |

| Bending speed* [ipm] | 47,2 | 47,2 | 42,5 | 42,5 |

| Maximum stroke [in] | 13,8 | 13,8 | 17,7 | 17,7 |

| Table-ram distance OH [in] | 23,6 | 23,6 | 27,6 | 27,6 |

| Total lenght B [in] | 169,7 | 209 | 209,8 | 171,6 |

| Total width P [in] | 68,3 | 68,3 | 81,8 | 81,8 |

|

Total height H [in] |

129,7 | 129,7 | 145,9 | 145,9 |

|

Maximum electrical consumption [kW] |

20 | 20 | 20 | 26 |

| Pound [lb] | 25794 | 29762.4 | 42769.6 | 37478.5 |

| Model | 220/4250 | 220/5100 | 220/6100 | 320/3000 |

| Maximum bending force [US Tons] | 242 | 242 | 220 | 352 |

| Table length L [in] | 167 | 200 | 240 | 120,4 |

| Distance between side frames I [in] | 142 | 181 | 220 | 103 |

| Throat depth TD [in] | 20 | 20 | 20 | 20 |

| Maximum speed [ipm] | 519,7 | 519,7 | 425,1 | 519,7 |

| Bending speed* [ipm] | 42,5 | 42,5 | 42,5 | 42,5 |

| Maximum stroke [in] | 17,7 | 17,7 | 17,7 | 17,7 |

| Table-ram distance OH [in] | 27,6 | 27,6 | 27,6 | 27,6 |

| Total lenght B [in] | 209,8 | 249,2 | 291,3 | 172,4 |

| Total width P [in] | 81,8 | 81,8 | 81,8 | 82 |

|

Total height H [in] |

145,9 | 145,9 | 145,9 | 147,8 |

|

Maximum electrical consumption [kW] |

26 | 26 | 26 | 39 |

| Pound [lb] | 42769.6 | 47399.3 | 51808.6 | 48060.7 |

| Model | 320/4250 | 320/5100 | 400/4250 |

| Maximum bending force [US Tons] | 352 | 352 | 441 |

| Table length L [in] | 167 | 200 | 167 |

| Distance between side frames I [in] | 141 | 181 | 141 |

| Throat depth TD [in] | 20 | 20 | 20 |

| Maximum speed [ipm] | 519,7 | 519,7 | 519,7 |

| Bending speed* [ipm] | 42,5 | 42,5 | 42,5 |

| Maximum stroke [in] | 17,7 | 17,7 | 17,7 |

| Table-ram distance OH [in] | 27,6 | 27,6 | 27,6 |

| Total lenght B [in] | 210,6 | 250 | 210,6 |

| Total width P [in] | 82 | 82 | 82 |

|

Total height H [in] |

147,8 | 147,8 | 147,8 |

|

Maximum electrical consumption [kW] |

39 | 39 | 45 |

| Pound [lb] | 55115.5 | 66138.6 | 59524.8 |

| Model | AU-TO 170/4250 |

AU-TO 220/4250 |

| Maximum bending force [US Tons] | 187 | 242 |

| Table length L [in] | 167** | 167 |

| Distance between side frames I [in] | 143 | 142 |

| Throat depth TD [in] | 17 | 20 |

| Maximum speed [ipm] | 590,6 | 519,7 |

| Bending speed* [ipm] | 47,2 | 42,5 |

| Maximum stroke [in] | 13,8 | 17,7 |

| Table-ram distance OH [in] | 23,6 | 27,6 |

| Total lenght B [in] | 218,9 | 218,9 |

| Total width P [in] | 85,4 | 88,1 |

|

Total height H [in] |

129,5 | 145,2 |

|

Maximum electrical consumption [kW] |

20 | 26 |

| Pound [lb] | 34171.6 | 47619.8 |

* Bending speed regulated by current standards.

** Automatic tools set up L = 3060 mm

Salvagnini reserves the right to modify this data without prior notice.