ROBOformER - Robotic bending cell

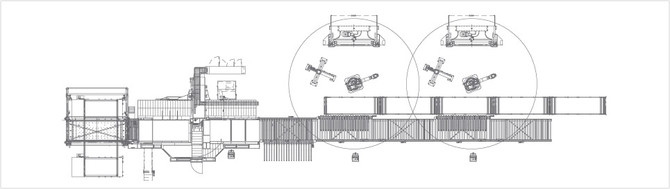

The robot:the protagonist of automation.

Thanks to the service robot and automatic loading/unloading devices, the cell with two levels of automation - process and operation - is a reliable solution for unattended production, even at night.

All risks associated with part handling during bending are faced by the robot and not by the operator.

| Model | KR16 | KR60L45 | KR150L110 | KR240L180 | KR240L210 |

| Fast, high dynamics | Flexible, suited for small-sized part handling | Versatile, suited for medium-sized part handling | Powerful, suited for medium-sized part handling | On tracks, specific for heavy duty handling | |

| Payload (Kg) | 16 | 45 | 110 | 180 | 210 |

| Max. range of action (mm) | 1610 | 2230 | 3100 | 3100 | 2900 |

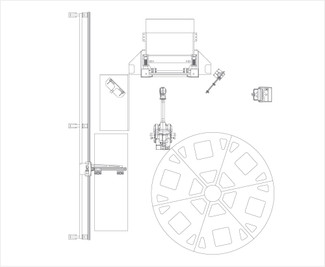

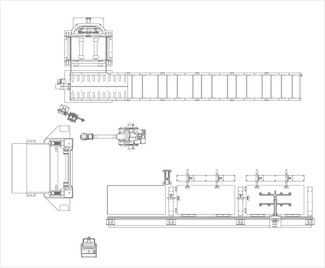

Connections

The ROBOformER can be equipped with different types of loading and unloading connections, depending on the client’s production requirements.

- Loader from a precentred pack.

- Loader from a Cartesian feeder in masked time.

- Cartesian feeder with controlled axes.

- Feeder/unloader for connection in line with Salvagnini systems.

- Unloader.

- Carousel unloader.

- Roller-surface unloader for pallets.

- Roller-surface unloader for pallets and crates.

Configurations