S1 - Mechatronic punching machine

- MULTI-PRESS HEAD

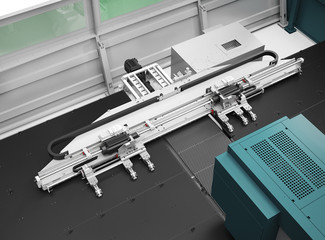

- TWIN MANIUPLATOR

- LASER CUTTING

Multi-press head with advanced hybrid technology

S1 embeds the latest second generation multi-press punching head, featuring advanced hybrid technology. The hybrid drive, previously applied in the Salvagnini lean panel benders, allows high quality punching, thanks to a patented architecture and to sophisticated cycles. The intelligent use of latest generation components and the original solution in which the system and electric motor are sized not for full punching power, but for a fraction of it, made it possible to reduce energy absorption by 20% in comparison to common electrical solutions available on the market, which also results in a reduction in component dimensions and costs, thereby minimizing maintenance.

Thick turret tools, always available

The Salvagnini multi-press has always been a unique solution in the market, as it is able to simultaneously manage one or more tools and does not need to stop for tool change. This makes punching incomparable in terms of cycle time and tool wear and makes the process extremely productive and efficient. The multi-press head uses standard thick turret tools type B, C and D. They allow greater versatility, they widen the range of thicknesses that can be punched compared with other Salvagnini punching centers, they guarantee the highest punching and embossing quality thanks to their controlled descent.

Head configuration

The rotating stations can house multitool tools, configured as follows:

10 with Ø maximum 18 mm

6 with Ø maximum 24 mm

4 with Ø maximum 31.7 mm

1 with Ø maximum 88.9 mm

| Maximum number of punching stations | 14 | ||||

| Maximum number of tools | 41 | ||||

| Lower and upper head gap (mm) | 18 | ||||

| Maximum embossing height (mm) | 18 | ||||

| Type of thick turret tools | B, C and D | ||||

| Number of B-type stations Ø 31.7 mm | 6 | ||||

| Number of C-type stations Ø 50.8 mm | 5 | ||||

| Number of rotation D-type stations Ø 88.9 mm | 3 | ||||

| Options | |||||

| Embossing stations (maximum number) | 6 (2B, 2C, 2D) | ||||

| Electric tap | installed to the side of the head | ||||

Twin manipulator with variable set-up

The twin manipulator, equipped with two independent trolleysmoving along X axis, centers the metal sheet when cycle starts and keeps it clamped during the punching and cutting operations. The two trolleys can operate simultaneously or independently and each of them features 3 independently extended opening pincers, one with a variable set-up: this configuration allows to work in the entire areas of the sheet, including those with embossing or on long and narrow formats, guaranteeing 100% sheet utilization. All parts of the sheet can be reached, thanks to an intelligent path and punching optimization algorithm, which manages the movements of the two trolleys and the extended pincers.

Laser cutting for limitless design

The fiber laser cutting head, positioned to the side of the multi-press head, moves on a carriage along the Y-axis with a 290 mm stroke: it guarantees maximum freedom in cutting geometries and it is responsible for the final cut of the part. The 2000 or 3000 W fiber laser source makes it possible to achieve high linear cutting speeds as well as absolute precision when making irregular contours.