L5 - high dynamics fiber laser

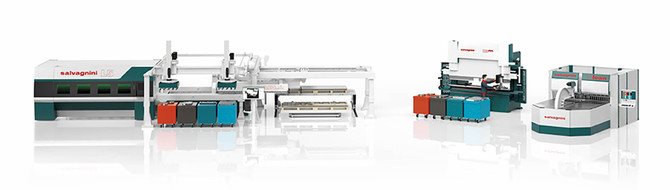

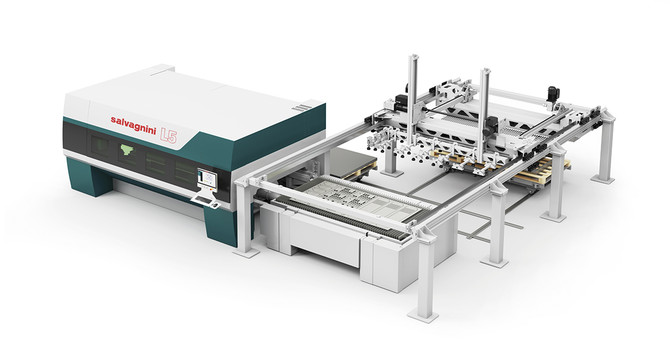

Adjustable automation catering to all production requirements

The L5 can be set up in various ways according to the different loading and unloading requirements and machine models.

The L5 is supplied in a standard configuration with the CP pallet changer. The optional CPS alternative solution allows unmanned operation because, during the pallet exchange phase, the table with the processed sheet always travels beneath the table with the blank to be cut.

Furthermore, the ADB, ADL and ADLL automatic loading connections are available to allow the blanks to be picked up automatically from a pack of sheets in masked time. The ADL and ADLL allow not only sheet loading but also workpiece unloading to be automatized, eliminating the intermediate handling phases that are generally entrusted to the operator; furthermore, they can be integrated with compact or extended pack store-towers (MBT, MV).

Automation can also include the modular MTW mini-stores offering a wide variety of sheet storage positions and layout solutions, or the smaller LTWC and LTWS single-tower stores for unmanned loading, unloading and storage of material.

The MCL is the automatic solution for unloading, separating and stacking. It is equipped with two rotating manipulators, each of which is fitted with independent suction cups that work separately or simultaneously. Unique on the market, it is fully integrated with the machine control and software for maximum flexibility. It handles parts weighing up to 130 kg.

Continuous improvement

The L5 laser is designed for the future, to evolve and meet the demands of ever-changing manufacturing trends and to be easily integrated with automatic manipulation devices in 4.0 factories.

Integrated communication and JIT-production

Thanks to the proprietary software, the L5 laser can exchange information with the company ERP or communicate with other systems. For instance, machine programs can be created from production orders, and information on production can be returned automatically. In an FMC cell, on the other hand, where the laser is integrated with bending centers downstream, integration software enables production flows to be optimized between systems so as to increase productivity and reduce waste and waiting times.