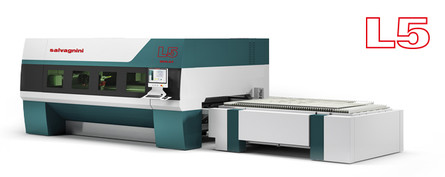

P1 - Versatile and productive electric panel bender

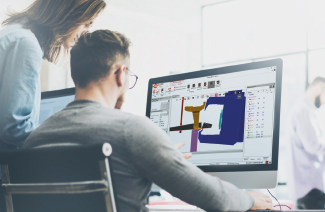

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid part code turnover. STREAM is Salvagnini’s answer to the modern industrial context, a programming suite that improves reactivity andreduces costs, operating errors and process inefficiencies. STREAM is the integrated environment for managing all activities in the office and on the factory floor, the only point of access for all technologies, from cutting to bending, meeting all planning, programming, production, management, control and optimization needs throughout the production process. Moreover STREAM can be used to calculate costs, including upstream and downstream processes where necessary.

STREAMBEND is the software for developing panel bending programs, including multiple parts:

- in automatic mode, it develops programs independently, starting from a 3D model;

- in interactive mode, it is used for generation/editing/completion operations.

It includes a simulator that can assess the results obtained on the machine.

PARTS is the software used to manage the whole database of products and parts:

- it classifies the elements according to common or customized categories;

- it defines the production flows for each part to be machined;

- it generates the relative programs.