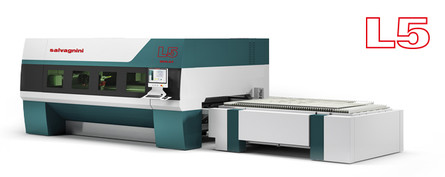

P2 - Flexible bending solution

Technical data

Salvagnini offers three P2 models to bend up to 2500 mm in length and 254 mm in height, to meet all production needs, and to maximize the use of the panel bender.

- MM

- INCHES

|

Model |

P2-2120 | P2-2225 | P2-2520 |

|

Maximum length of incoming sheet [mm] |

2495 | 2815 | 2795 |

|

Maximum width of incoming sheet [mm] |

1600 | 1524 | 1600 |

|

Maximum diagonal that can be rotated [mm] |

2500 | 2820 | 2800 |

|

Maximum bending force [kN] |

330 | 590 | 660 |

|

Maximum clamping force [kN] |

530 | 635 | 1060 |

|

Maximum bending length [mm] |

2180 | 2200 | 2500 |

|

Maximum bending height [mm] |

203 | 254 | 203 |

|

Minimum thickness [mm] |

0.4 | 0.5 | 0.5 |

| Maximum thickness and bending angle steel, UTS 410 N/mm2 [mm] | 3.2 (±90°) 2.5 (±120°) 2.1 (±135°) |

3.2 (±90°) 2.5 (±130°) 2.1 (±135°) |

3.2 (±90°) |

| Maximum thickness and bending angle stainless steel, UTS 660 N/mm2 [mm] | 2.5 (±90°) 2.1 (±120°) 1.6 (±130°) |

2.5 (±90°) 2.1 (±125°) 1.6 (±135°) |

2.5 (±90°) 2.1 (±125°) 1.6 (±135°) |

| Maximum thickness and bending angle aluminium, UTS 265 N/mm2 [mm] |

4.0 (±120°) |

4.0 (±120°) |

4.0 (±120°) 3.5 (±130°) 3.0 (±135°) |

| Average consumption [kW] | 3.0 | 4.0 | 5.0 |

|

Noise level (Machine Directive 2006/42/EC) [dB] |

68 | 68 | 69 |

Values refer to a standard machine. Salvagnini reserves the right to modify this data without prior notice.

| Model | P2-2120 | P2-2225 | P2-2520 |

|

Maximum length of incoming sheet [in] |

98.23 | 137.6 | 110.03 |

|

Maximum width of incoming sheet [in] |

63 | 60 | 63 |

|

Maximum diagonal that can be rotated [in] |

98.43 | 137.8 | 110.23 |

|

Maximum bending force [kN] |

330 | 625 | 660 |

|

Maximum clamping force [kN] |

530 | 825 | 1060 |

|

Maximum bending length [in] |

85.83 | 122 | 98.42 |

|

Maximum bending height [in] |

8 | 10 | 8 |

|

Minimum thickness [gage] |

27 | 25 | 25 |

| Maximum thickness and bending angle steel, UTS 59500 psi [gage] | 11 (±90°) 13 (±120°) 14 (±135°) |

11 (±90°) 13 (±130°) 14 (±135°) |

11 (±90°) 13 (±130°) 14 (±135°) |

| Maximum thickness and bending angle stainless steel, 59500 psi [gage] | 13 (±90°) 14 (±120°) 16 (±130°) |

11 (±90°) 14 (±125°) 16 (±135°) |

13 (±90°) 14 (±125°) 16 (±135°) |

| Maximum thickness and bending angle aluminium, UTSUTS 38500 psi [gage] | 7 (±120°) 8 (±130°) |

7 (±120°) 8 (±130°) 9 (±135°) |

7 (±120°) 8 (±130°) 9 (±135°) |

| Average consumption [kW] | 3.0 | 4.0 | 5.0 |

|

Noise level (Machine Directive 2006/42/EC) [dB] |

68 | 68 | 69 |

Values refer to a standard machine. Salvagnini reserves the right to modify this data without prior notice.