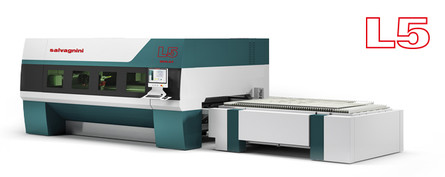

S4 - Integrated punching-shearing center

S4 software

The chain composed of the Salvagnini SiX numerical controller and the excellent automation software solutions developed in-house guarantees operating flexibility and a high rate of production with consistently accurate parts.

JOB.CONSOLE.S4

JOB.CONSOLE is the set of software packages that are integrated into the SiX controller to graphically manage and supervise the system. JOB.CONSOLE provides the operator with all the information he needs to run production, thanks to the following modules:

Maintenance Manager

Database that analyzes the movements and cycles of the components of the system, allowing simple and structured management of maintenance activities.

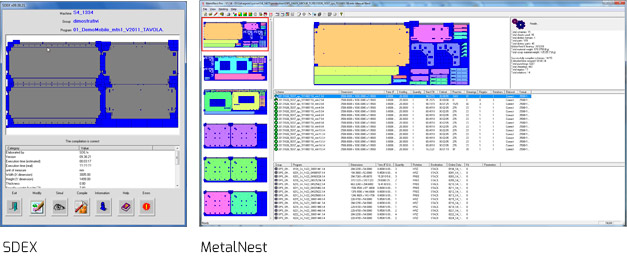

SDEX

Salvagnini compiler that interprets programming instructions based on geometrical notions and defines the production cycle, optimizing sheet movements and cycle times.

JOBS4

Software that dynamically programs the day’s production: the operator can create a series of programs called “job” (or list) on the screen. JOBS4 allows a series of jobs to be prepared, edited or suspended, without stopping the current production.

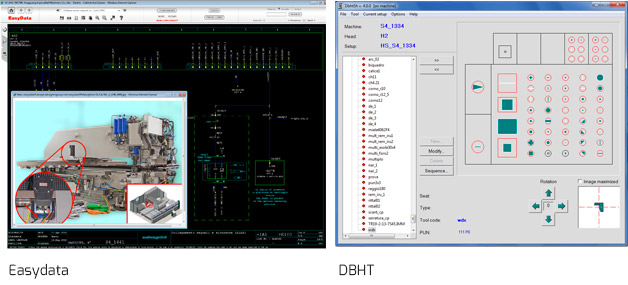

DBHT

Graphical database that checks the punching tools present in the operating head. The system warns the operator if the punch set-up defined is not compatible with the part to be produced.

EasyData

Integrated diagnostic software for interactively browsing the documentation. EasyData provides information about each of the components managed by the Salvagnini controller, using photos, part codes and automatic filters. The system’s electrical and/or hydraulic diagrams are available in the main command console. The operator can:

- expand the image archive or search for specific text or codes in the diagrams;

- add personalized notes or photos to the image archive;

- print one or more diagrams from the documentation or export them in PDF or JPG format.

Office Console

The OFFICE.S4 software package allows fast, user-friendly offline programming of Salvagnini punching machines from office workstations.

It can include:

- SimulX: process simulator

- MetalNest: nesting program

- Campunch: CAM software

- Impunch: Reverse-engineering software